Collision frame repair involves skilled technicians using laser measurement and visual inspection to assess damage, identify structural weaknesses, and determine repair needs for classic cars or newer vehicles. Top-tier shops consider age, condition, rust, and previous repairs, using specialized tools like hydraulic presses, piecemeal racks, high-quality paints, and jack stands to ensure precision, quality, and safety in every step of the process, from workspace preparation to welding and painting, ultimately achieving reliable vehicle restoration.

In the realm of automotive restoration, collision frame repair is a meticulous art. When a vehicle sustains damage, assessing the extent of the collision frame injury is crucial. This article explores best practices for tackling this intricate process efficiently. From understanding the types of collision frame damage to procuring the correct tools and equipment, we guide you through every step. Learn how to restore structural integrity safely and effectively, ensuring your repairs stand the test of time.

- Understanding Collision Frame Damage Assessment

- Correct Tools and Equipment for Repairs

- Step-by-Step Guide to Restoring Structural Integrity

Understanding Collision Frame Damage Assessment

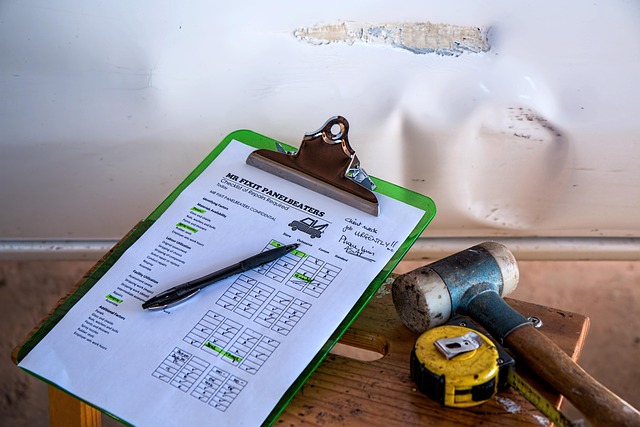

Collision frame damage assessment is a critical step in effective collision frame repair work. It involves meticulously examining the vehicle’s structural integrity, identifying areas of deformation, and determining the extent of the damage. Skilled technicians use various tools and techniques, such as laser measurement devices and visual inspection, to accurately assess bends, cracks, or displacement in the frame. This process not only helps in understanding the scope of repairs needed but also ensures that every component is addressed for a safe and reliable restoration.

A top-notch car repair shop specializing in collision frame repair will go beyond basic assessment. They’ll consider factors like the age and condition of the vehicle, especially in the case of classic car restoration projects, where preserving historical integrity is paramount. Auto body repair experts will also look for signs of previous repairs, rust, or hidden damage to provide a comprehensive evaluation. This thorough approach guarantees that any structural weaknesses are corrected, preventing future issues and ensuring the vehicle’s safety on the road.

Correct Tools and Equipment for Repairs

When undertaking collision frame repair work, having the right tools and equipment is paramount to ensuring precision and quality. For instance, specialized tools designed for straightening metal, such as hydraulic presses and piecemeal racks, play a crucial role in realigning damaged panels and restoring the vehicle’s structural integrity. Additionally, high-quality paints and applicators are essential for seamless car paint repair, providing a durable finish that matches the original specifications of the vehicle.

Body shop services relying on top-tier equipment and materials can significantly enhance their collision frame repair capabilities. Moreover, fleet repair services benefit from these investments as they enable faster turnaround times and higher levels of consistency in their work, catering to the demands of businesses with large vehicle fleets. Ultimately, adhering to best practices and utilizing proper tools contributes to high-quality outcomes for any collision frame repair project.

Step-by-Step Guide to Restoring Structural Integrity

Restoring a vehicle’s structural integrity after a collision is a meticulous process that requires precision and expertise. Here’s a step-by-step guide for successful collision frame repair, focusing on both efficiency and safety.

1. Safety First: Begin by ensuring the workspace is secure and clear of any hazards. Use jack stands to support the vehicle properly, maintaining stability throughout the repair process. This prevents further accidents and ensures the mechanic’s safety.

2. Assess Damage: Carefully inspect the frame for dents, cracks, or misalignments. Utilise advanced technology such as laser alignment tools for accurate measurements. This step is crucial in determining the extent of the damage and guiding the subsequent repairs.

3. Frame Straightening: Employ state-of-the-art frame straighteners to return the metal to its original shape. This process involves carefully applying pressure to realign the bent or crushed sections, ensuring the vehicle’s structural integrity is regained.

4. Panel Replacement: For damaged panels, use high-quality replacement parts specific to the vehicle make and model, such as those available for Mercedes-Benz repairs. Precise cutting and fitting techniques are employed to ensure a seamless finish, matching the original auto body shop precision.

5. Welding and Painting: Skilled technicians perform meticulous welding to secure all repaired areas. Following this, a thorough painting process using industry-standard paints ensures not just aesthetic restoration but also long-lasting protection against future corrosion.

Effective collision frame repair requires a comprehensive understanding of damage assessment, the right tools, and meticulous steps to restore structural integrity. By adhering to these best practices, professionals can ensure vehicles return to their pre-accident condition, enhancing safety and customer satisfaction in the process. Collision frame repair is not just about fixing metal; it’s about bringing peace of mind to those who rely on their vehicles.